Ferrotitanium

Production process: Ferrotitanium is an alloy composed of titanium and iron. The process of producing ferrotitanium usually involves mixing titanium and iron raw materials and reacting at high temperatures.

Phone

+8618864897033

info@cn-ores.com

+8618864897033

Related products

Production process: Ferrotitanium is an alloy composed of titanium and iron. The process of producing ferrotitanium usually involves mixing titanium and iron raw materials and reacting at high temperatures.

Raw material preparation: Prepare titanium and iron raw materials. The main source of titanium is ilmenite (such as titanomagnetite), while the source of iron can be iron ore. These raw materials undergo treatment steps such as ore crushing, crushing and sorting to ensure that they have the required chemical composition and particle size.

Specifications and granularity: natural block, 10-100mm, 10-60mm, 3-10mm, 1-3mm, 0-1mm or customized according to customer requirements.

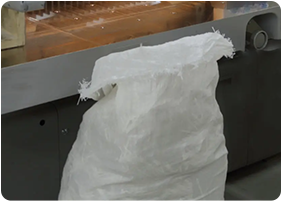

Packaging: ton bag packaging (1000kg/bag) or customized according to customer requirements.

Purpose

Ferrotitanium has a variety of uses in industry, the following are some of the main application areas:

Iron and steel production: Ferrotitanium is commonly used as an additive to improve the properties of steel. It can increase the hardness, strength and corrosion resistance of steel, while reducing the oxidation and brittleness of steel. Therefore, ferrotitanium is widely used in the production of steel products such as stainless steel, alloy steel and high-strength steel.

Casting industry: Because of its good fluidity and corrosion resistance, ferrotitanium is used as a casting material in the casting industry. Ferrotitanium can be used in the production of various parts and assemblies, such as automotive engine parts, industrial machinery parts, and aerospace equipment.

Specification

| FERRO TITANIUM | |||||||

| ITEM | CHEMICAL% | ||||||

| T1% | AL | Si | P | S | C | Mn | |

| MAX | |||||||

| FeTi30-A | 25-35 | 8.0 | 4.5 | 0.05 | 0.03 | 0.10 | 2.5 |

| FeTi30-B | 25-35 | 8.5 | 5.0 | 0.06 | 0.04 | 0.15 | 2.5 |

| FeTi40-A | 35-45 | 9.0 | 3.0 | 0.03 | 0.03 | 0.10 | 2.5 |

| FeTi40-B | 35-45 | 9.5 | 4.0 | 0.04 | 0.04 | 0.15 | 2.5 |

| FeTi70-A | 65-75 | 3.0 | 0.5 | 0.04 | 0.03 | 0.10 | 1.0 |

| FeTi70-B | 65-75 | 5.0 | 0.4 | 0.06 | 0.03 | 0.20 | 1.0 |

| FeTi70-C | 65-75 | 7.0 | 0.5 | 0.08 | 0.04 | 0.30 | 1.0 |

Product Process

Raw material mining

Ore crushing and crushing

Ore smelting

Cooling and solidification of alloy

Synthetic crushing and processing

Product packaging

QC

Warehousing and Logistics