FeMn60Si 14

Using silicon-manganese alloy to make steel, the melting points of deoxidation products MnSiO₃ and Mn₂SiO₄ are 1270 ℃ and 1327 ℃ respectively, which have the advantages of low melting point, large particle size, easy to float, and good deoxidation effect.

Phone

+8618864897033

info@cn-ores.com

+8618864897033

Related products

Using silicon-manganese alloy to make steel, the melting points of deoxidation products MnSiO₃ and Mn₂SiO₄ are 1270 ℃ and 1327 ℃ respectively, which have the advantages of low melting point, large particle size, easy to float, and good deoxidation effect.

Specifications: Natural block, 10-100mm, powder or customized according to customer requirements.

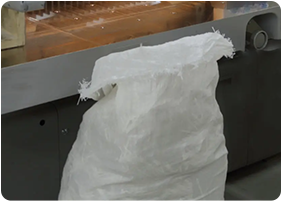

Packaging: waterproof, woven bag ton Packaging (1000KG per bag)

Specification

|

Brand |

Chemical composition % |

||||

|

Mn |

Si |

C |

P |

S |

|

|

FeMn60Si 14 |

60-70 |

14-17 |

(≤): 2.5 |

(≤): 0.30 |

(≤): 0.04 |

|

FeMn65Si 17 |

65-70 |

17-20 |

(≤): 2.0 |

(≤): 0.25 |

(≤): 0.04 |

|

FeMn68Si 18 |

65-72 |

17-22 |

(≤): 1.8 |

(≤): 0.25 |

(≤): 0.04 |

Application

Silicon-manganese alloy is an alloy composed of manganese, silicon, iron and a small amount of carbon and other elements. Silicon-manganese alloy is mainly used as the intermediate material of deoxidizer and alloying agent in iron and steel production, and also the main raw material of medium and low carbon ferromanganese production. Silicon-manganese alloys can also be smelted in continuous operation in large, medium and small submerged arc furnaces.

Product Process

Raw material mining

Ore crushing and crushing

Ore smelting

Cooling and solidification of alloy

Synthetic crushing and processing

Product packaging

QC

Warehousing and Logistics